‘A mobility issue is not only about mobility, there is always interaction with the rest of the world.’

Interview with Margriet van Schijndel and Tijs Donkers of the Eindhoven University of Technology, partner of the Battery Competence Cluster - NL.

Please introduce yourself!

My name is Margiet van Schijndel and I am program manager Responsible Mobility within EASI on the TU/e. EASI stands for Eindhoven AI Systems Institute. As the name suggests, we focus on AI or artificial intelligence. Mobility is an important element within all our faculties. That is why you can find our people throughout the university. I think that future mobility always needs some sort of battery. Data and AI can have a positive impact on the performance of battery technology.

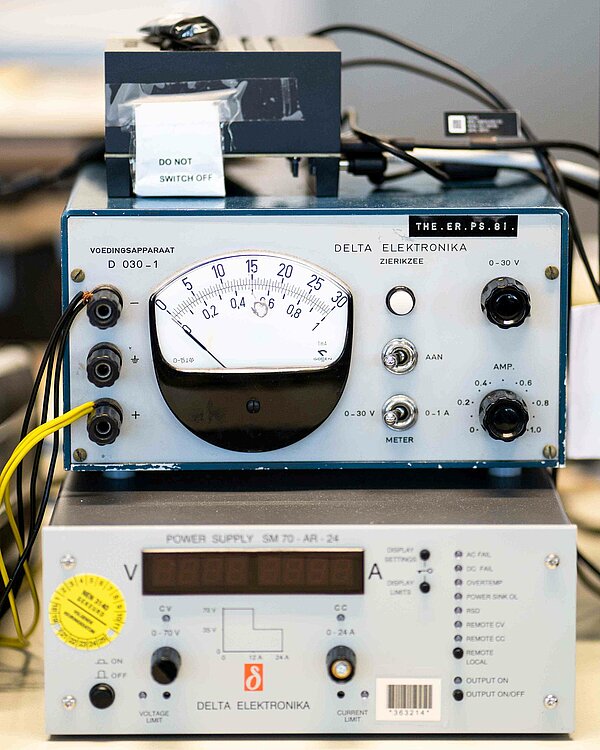

My name is Tijs Donkers and I am associate professor at the faculty of electrical engineering. I specialize in control engineering and I work a lot with batteries. I am no chemist, so I don’t open them up. For me, a battery is the same as for the average human being; it has a plus and minus pole and if you put it into a device, it will work. Or it won’t. When measuring a battery, data is generated and that is where my area of expertise comes in. We can use this data, which constitutes the link between battery technology and AI.

What does the TU/e do as part of the collaboration with the BCC and how are you involved?

Within the Battery Competence Cluster-NL, the TU/e focuses on predicting battery capacity and lifespan. But we also look at it from a wider perspective. For example, how do you design the whole system, or how can we design batteries to be more (energy) efficient from the start? The batteries in our phones are probably not the same batteries we need to create, and maintain, a sustainable and stable power grid. The power grid in the Netherlands is pretty congested. To solve that, we need new types of battery technologies. Besides, the disposal of old batteries is also something to consider, as batteries ultimately become chemical waste. How to set up a production process to ensure it is circular from the start?

We are already too late with respect to the batteries that are being used right now. That is why we are thinking up solutions to close the circle in the best way possible and we are developing knowledge to ensure the production process is circular from the start. Or, how do you determine your charging strategy based on the energy the larger power grid needs to supply? How do you respond and what effect does it have on the state-of-health of your battery? That is something we also do at the TU/e.

There is still much to explore in the field of battery technology. Besides the fact that we simply love most of the research, this is also what we focus on within the BCC. Within the cluster, the TU/e is the knowledge partner. We consider it our duty to develop the knowledge that is still needed and make it available to our partners within the BCC.

In what way is the TU/e helping to solve the global challenges?

Batteries are more than just a device; they are part of a system. They are manufactured, used and reused. Then they become waste, which we can hopefully use to create new things. We are the ones that consider the life cycle. In doing so, we also look at other applications, outside the mobility sector.

Take our power grid, for example, which is becoming increasingly dependent on batteries. On sunny days, the solar panels in the Netherlands generate a lot of energy, resulting in a grid that is becoming congested. We can translate the lessons learned from battery use in vehicles to solutions for storage of solar energy. We also generate innovations by using data in a targeted way in AI. However, energy is needed to use artificial intelligence. It might even have substantial impact on the life span and energy supply of your battery. What can we do about that? How can we make AI more future proof? Those are the topics that contribute to the research being conducted at the BCC. Our industrial partners focus on mobility, but a sustainable connection to the power grid is a Dutch problem.

The framework within which the Battery Competence Cluster-NL is working should therefore not be too restrictive. The BCC should also be able to establish a connection with the power grid. The Netherlands is a transport country; many goods are being transported by road via Dutch transport companies. Electric road transport requires a proper charging infrastructure and reliable batteries. A mobility issue is not only about mobility, there is always interaction with the rest of the world.

The TU/e is creating mathematical models to predict the behavior of a battery when used in a certain way in a certain vehicle. To be able to do this, we are collaborating with the local industry. They present us with an issue and jointly with TNO, for example, we verify if the models we have developed fit the measurements we see.

If the models are correct, we make them available to the industry. So they can use them to make predictions; ‘if we install a battery this way, this will be the expected life span.’ The many different queries we receive from the industry, make it very interesting for us as TU/e to participate in the BCC.

How will the innovations of the Battery Competence Cluster-NL affect the Dutch citizens?

The Automotive Campus in Helmond has significantly increased in size and activity. Without an ecosystem such as the BCC, that activity would not have been able to increase to such extent. And this activity stimulates innovation. The Netherlands doesn’t manufacture any batteries, but it is good at adding intelligence. It is knowledge-intensive work to assemble those modules and to add intelligence. You need qualified people to do that. At TU/e, we train these people by having them conduct research.

Of course, the transition to E-mobility has been underway for quite some time. However, the transition won’t succeed without innovation. It is not possible for everyone to drive electric today. We don’t have the batteries and the infrastructure needs innovation to be able to set up a sustainable mobility system. To tackle these issues, we need the partners within the BCC. We need each other to move forward, and we need all building blocks to make the change.

Everyone is impacted by the transition in one way or the other. When you are using solar panels or when you want to charge your car, you notice how congested the Dutch power grid is. However, many jobs are being created in the region because of the transition. And not only for academics, jobs are being created throughout the chain. Distribution within the urban network is becoming increasingly electric, but even there we are reaching the limits of what is possible and available. But the BCC is also creating solutions to solve those issues.

What parties do you want to work with to achieve success and what are the topics people can contact you for?

Collaboration is in our DNA. Of course, we are already collaborating with the partners within the BCC, but as far as we are concerned the cluster is never complete. We need people from outside the cluster to help us stay focused, so we know what the issues are, and to inspire one another and share knowledge. The BCC enables us all to collaborate, find each other, understand the added value of collaboration and continue to challenge each other. But we also have to look beyond the BCC. Both nationally and internationally, but also beyond the borders of the mobility system, at energy suppliers for example. Not the easiest job perhaps, but it is important for the region.